How effective is the laser cleaning machine in treating the paint layer on wood?

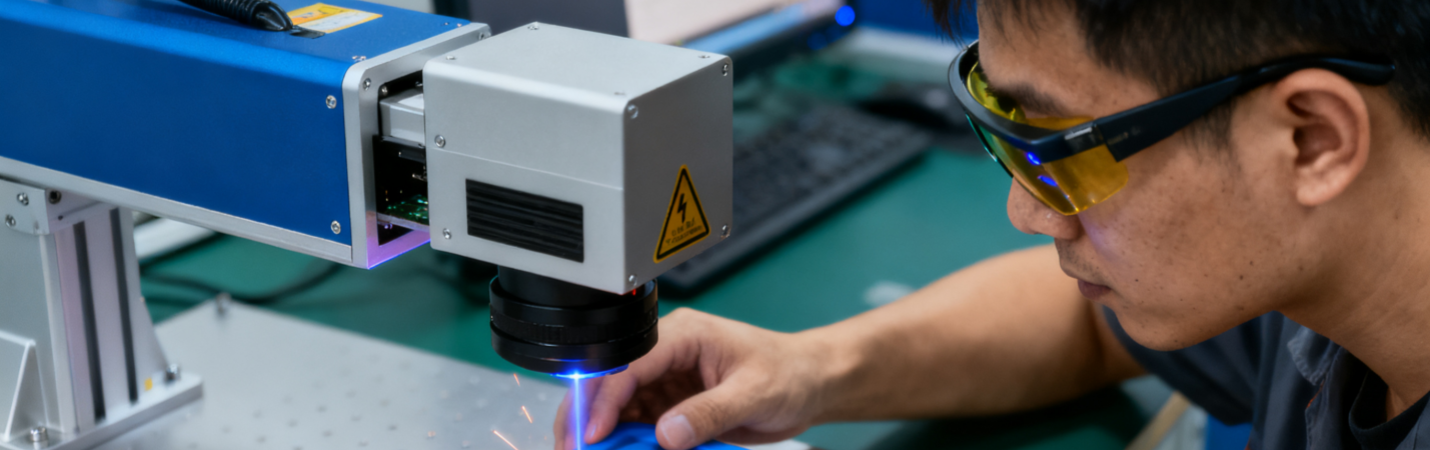

Laser cleaning is a highly effective and sophisticated method for treating paint layers on wood, but its effectiveness is highly dependent on several factors. It's not a one-size-fits-all solution, but in the right applications, it's unparalleled.Here’s a detailed breakdown of its effectiveness:Key Advantages (Why it's so effective)Extreme Precision and Control: The laser can be focused to a tiny spot (fractions of a millimeter), allowing for the selective removal of a specific paint layer without affecting the underlying wood or a sub-layer of historical paint. This is crucial for restoration work.Non-Contact and Non-Abrasive: Unlike sanding or scraping, there is no mechanical stress on the wood surface. This preserves the original patina, tool marks, carvings, and the delicate surface structure of aged wood.Eco-Friendly and Safe: It generates no chemical waste (unlike paint strippers) and minimal dust, which is easily captured by a filtration system. This is especially important when dealing with lead-based paints, as the hazardous vaporized material is contained.Layer-by-Layer Removal: By adjusting the laser parameters, operators can "dial in" the correct energy to remove the top layer of paint and then proceed to the next, allowing for controlled reveals of underlying history.Minimal Thermal Impact: Modern pulsed lasers (Nd:YAG or fiber lasers) deliver energy in extremely short pulses (nanoseconds), vaporizing the paint so quickly that heat doesn't have time to conduct into the wood substrate, preventing burning or charring.Crucial Factors Affecting EffectivenessPaint Composition and Color:Color: Darker paints (black, brown) absorb laser light much more efficiently than lighter ones (white, yellow), making them easier to remove. Multiple passes or adjusted settings may be needed for light colors.Type: Modern acrylics, oils, and traditional pigments all react differently. The presence of certain metal oxides in pigments can affect absorption.Age/Thickness: Hard, brittle, thick old paint often responds better than thin, gummy modern coatings.Wood Substrate:Species and Density: Hardwoods (oak, maple) with tight grain are ideal. Softwoods (pine) or weathered, low-density wood are more prone to thermal damage if settings are incorrect, as the laser might start to ablate the wood itself.Surface Condition: Charred, degraded, or uneven surfaces require extreme care. The laser will preferentially remove the weaker, degraded wood if the parameters are wrong.Moisture Content: Dry wood is generally safer to treat.Laser Parameters: The operator must expertly balance:Wavelength: Typically 1064 nm (infrared) is used, but other wavelengths can be better for specific pigments.Fluence (Energy Density): The energy delivered per unit area. Too low = ineffective; too high = risk of damaging the wood.Pulse Duration & Frequency: Shorter pulses minimize heat. The speed of the scanning head is critical for an even result.Limitations and ChallengesCost: The machinery is a significant capital investment, and the process can be slower than gross mechanical removal for large, simple surfaces.Operator Skill: It is not a "push-button" solution. Effectiveness relies entirely on a skilled operator who can "read" the surface and adjust parameters in real-time.Not for All Woods: As mentioned, very soft, resinous, or fragile wood can be problematic."Ghosting": Sometimes, a faint shadow or pigment residue can remain in the wood grain, which may require a very gentle final pass or a complementary cleaning method.Ideal ApplicationsHistorical Woodwork & Furniture Restoration: Removing overpaint from antique furniture, carved altars, paneling, or statues without losing the original finish or detail.Lead Paint Abatement: A safe, contained method for removing toxic lead paint from historic windows, doors, and trim.Fine Art Restoration: Cleaning of painted wood artifacts, frames, and sculptures.Selective Cleaning: Removing graffiti from wooden surfaces without damaging the substrate.ConclusionLaser cleaning is exceptionally effective for treating paint on wood when the goal is precision, conservation, and the preservation of the substrate. It is the gold standard for high-value, sensitive restoration projects where traditional methods are too destructive.However, its effectiveness is not automatic. It depends on the perfect marriage of:A suitable wood substrate.An experienced, knowledgeable operator.The correct laser technology and settings.For bulk paint stripping on robust, non-historical timber, traditional methods might be more cost-effective. But for any work where the wood itself is of value, laser cleaning is a revolutionary and highly effective tool.Recommendation: Always test on an inconspicuous area first to determine the optimal parameters for that specific combination of paint and wood.

Read more